Feedstock to Biofuels Opportunities for advanced biofuel

AUTHORS: Dr. Alok Satlewal, Research Manager, Ravi P. Gupta, General Manager, Dr. SSV Ramakumar, Director (R&D and P&BD), IndianOil R&D Centre

IEA Bioenergy Task 39 (transport biofuels) commissioned India to lead a study on “Feedstock-to-biofuels”, especially a biomass supply chain assessment for the production of 2nd Generation (2G) ethanol, to help understand the developments in India and other groups/member countries. The study mainly focussed on biomass availability, prevalent biomass supply chain approaches, and different process schemes, including the type of pretreatment technologies used by 2G ethanol technology developers. Furthermore, the study included life cycle analysis and environmental impact assessment to identify the GHG emissions and energy consumption hotspots during the lignocellulosic bioethanol production process.

Currently, the costs of most advanced biofuels options are much higher than those of conventional biofuels and their fossil fuel competitors; therefore, one of the objectives of this study was an urgent need is to identify the hotspots and opportunities for cost reduction by allowing larger economies of scale, in combination with the significant “learning effect” that occurs in technology development. This study might help identify all the potential opportunities across the feedstock-to-biofuel supply chain to reduce capital and operating costs for advanced biofuels production.

Accordingly, the authors surveyed the prior art and inputs from various references. Inputs covering some of the above aspects were acquired from IEA Bioenergy Task 39 representatives of the USA, Brazil and Germany. All the information were collated into this consolidated report.

The key findings of the report are as follows:

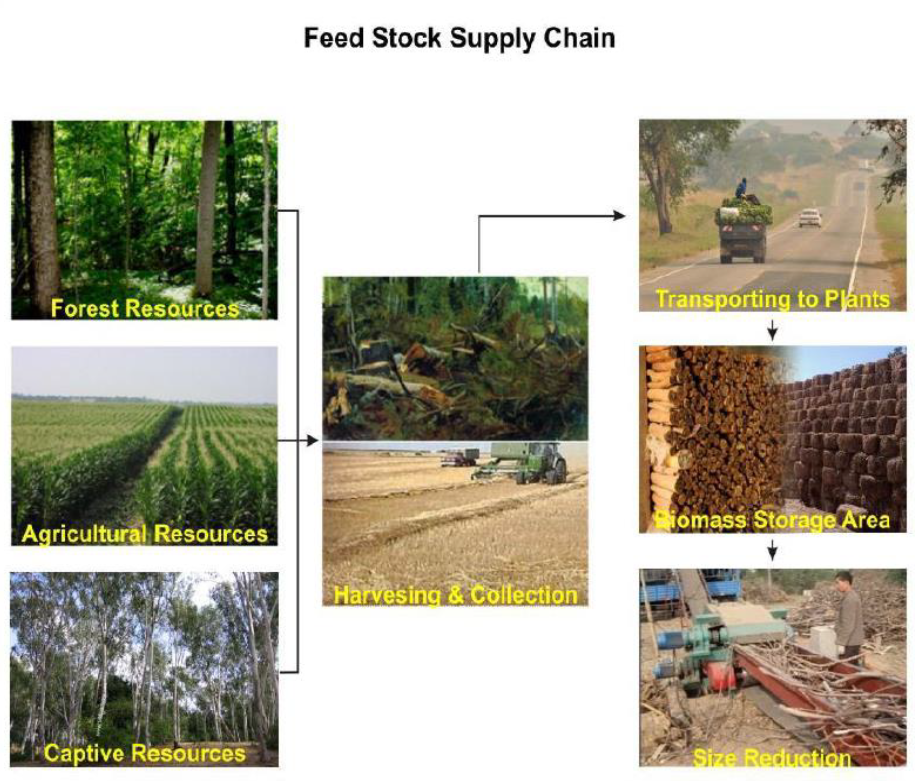

- The report mainly focuses on the biomass availability specific to these regions, variation in the chemical composition, biomass supply chain approaches, different process schemes, including the type of pretreatment technologies by 2G ethanol technology developers.

- Although 2G ethanol technologies are available in India, Brazil, Germany and the USA, these technologies are not economically competitive with fossil fuels or conventional biofuels at current Capex and Opex.

- Feedstock availability, capital cost, and production cost are the key challenges towards sustainable and commercial production and implementation of 2G ethanol technology.

- In India, most agri-businesses falter in performance in the medium to long term due to the failure to address raw material availability issues. Entrepreneurs/investors looking at establishing 2G ethanol plants consider the continued availability of required quantities of cellulosic raw materials at predictable price ranges as one of their top priorities.

- In India, the time gap between two crops is low. Therefore, farmers burn biomass residues, especially rice straw (generated after harvesting), to clear the fields for the next crop. Since the farmers have limited resources and low exposure to advanced technologies, it would be prudent for entrepreneurs to invest in the mechanization of the harvesting and baling process.

- Without reducing biomass quality caused by seasonal weather variations, biomass storage is also critical for ensuring the sustainability of 2G bioethanol plant operations year-round. Thus, stakeholders need to conduct a focused study, explore opportunities, and develop models to find a practical solution to store biomass and make it available year-round. Biomass logistics should be monitored well, since each operation where biomass is handled, increases the dust (i.e. ash content). This will lead to high transport costs and potential problems (in terms of biomass treating) into the biochemical reactors (e.g. rocks can block the stirrers).

- A good strategy would be investing in a supply chain business comprising procurement/collection, aggregation, baling, and storage before investing in the bioethanol plants. This would give them first-hand knowledge of the challenges involved and improve the confidence levels of their bankers and stakeholders as well.

- In India, some established supply chain models such as ITC E-Choupal Model, Amul Model, NDDB Safal model are applied in rural India for Agri-produced Logistics. These models have been designed to tackle the challenges posed by the unique features of Indian agriculture, characterized by fragmented farms, weak infrastructure and the involvement of numerous intermediaries. Such types of models may be applied for biomass supply chain management.

- Production of cellulolytic enzymes and their application for fermentable sugar production is identified as a hotspot to further reduce GHG emissions.

- The utilization of solid waste, generated from the bioethanol plant, to generate power and subsequently replace the fossil-derived energy requirements of the bioethanol plant can play a major role in reducing the GHG emissions of the 2G bioethanol production process.

- To address the Opex cost of production of 2G ethanol, there is an urgent need to develop cost-effective pretreatment technology with low or no chemicals, indigenous 2G enzyme technology with an onsite enzyme production model, and the valorization of lignin-rich residues to produce high-value chemicals. These technologies can make 2G ethanol cost competitive compared to 1G ethanol costs.

Figure: Typical Components of the Feedstock Supply Chain