To be or not to be a biobased commodity

Assessing requirements and candidates for lignocellulosic biomass-based commodities

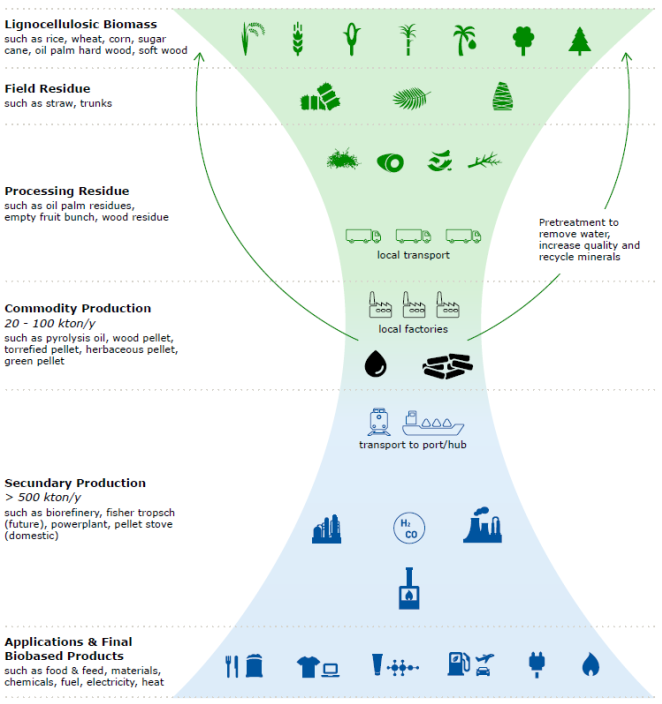

In 2018, IEA Bioenergy Task 43 (biomass supply) launched an initiative to identify successful examples of biomass logistics and distribution points for bioenergy and the bioeconomy: bio-hubs. Pre-treatments and densification at these bio-hubs allow transforming raw biomass feed streams into commodities with uniform properties. Commodities can then be shipped for remote downstream processing at industrial scale. Commoditization facilitates biomass supply chains so that biomass can play an increasing role to provide credible alternatives for geopolitically sensitive fossil fuel imports and thereby improve our energy security.

This report, carried out by Wageningen Food & Biobased Research, and financially supported by IEA Bioenergy Task 43 looks into requirements and candidates for lignocellulosic biomass-based commodities.

The full report is available here:

Report – To be or not to be a biobased commodity

What makes a true lignocellulosic commodity?

Lignocellulosic biomass is an underutilised renewable resource. Using this biomass for biobased applications is hampered by a lack of possibilities to efficiently link the biomass to markets which include both energy applications such as heat and electricity production, conversion to transport fuels, chemicals and/or other materials in biorefineries. Siting conversion facilities near abundant biomass has the benefit of availability of low-cost biomass, but the locations generally lack security of supply, availability of qualified personnel, and do not benefit from existing infrastructure and possibilities to add value to residues. Furthermore, the scale of conversion systems is limited by local cost of generally bulky and wet biomass supply.

Lignocellulosic biomass needs to be processed before (long distance) transport to increase energy density and ease of transportation, handling and storage. This can be done through a wide range of processes such as pelletisation, chipping, pyrolysis, torrefaction, or hydrothermal upgrading. This will require cost of pre-processing but will reduce cost of transportation, handling and storage and further conversion and in the end the overall cost of supply.

The development of real lignocellulosic commodities can connect biomass to markets and lower the opportunity costs of the commodities.

Five requirements of a real lignocellulosic biobased commodity have been defined:

- Easy to store and transport: High energy density, dry, low ash, nutrient depleted

- Fungible: “interchangeable”= uniform, standard quality

- Standardization of transport, contracting, insurance and conversion systems

- Functioning markets: trading systems, financial instruments (futures, etc.), high tradability

- Sustainability: Standard sustainability certification systems

Several candidates as real commodities exist including wood pellets, pyrolysis oil, herbaceous pellets, torrefied pellets, wood chips and bio-crude. However, they are still not real commodities as they do not fulfil the 5 requirements described above. It is argued that only a few biomass commodities have to be defined that cover all lignocellulosic biomass types (wood, grass, straw, bagasse, processing residues, etc.) and also all applications such as heat, electricity, fuels, chemicals and materials. The standards have to be as wide as possible and avoid frivolous or unnecessary demands. It will require international collaboration to materialize the potential lignocellulosic biomass. The development of real lignocellulosic commodities can connect biomass to markets and lower the cost of biomass supply by lowering transaction costs, as illustrated in the Figure. Commodities can contribute to efficient and circular use of biomass by creating a market for biomass that is currently highly underutilized (stranded biomass).

Development of biobased commodities

Trade in biomass will be greatly enhanced with the definition of a limited number of standard ‘biobased commodities’ that cover all lignocellulosic biomass types (wood, grass, straw, bagasse, processing residues, etc.) and also all applications such as heat, electricity, fuels, chemicals and materials. It is necessary that all parties involved in the production chain (biomass producers, machine builders, regulators, insurers, bankers, transport, final users) work towards creating these commodities that can link all the potentially available and diverse lignocellulosic biomass resources worldwide with global markets.

Figure: The role of biobased commodities to link lignocellulosic biomass sources to international markets. The arrows signify the return of minerals and water to the land or farm.