BECCUS case study: sequestering CO2 from ethanol production in the United States

BECCUS case study: sequestering CO2 from ethanol production in the United States

Up until recently, Bio-CCS was primarily discussed in terms of its potential and drawbacks over very long timeframes, e.g., 2050 and beyond, but there is now growing focus on more near-term aspects. The IEA Bioenergy inter-task project Deployment of BECCS/U Value Chains – where S is for storage, U is for Utilisation – strives to provide insights about the opportunities and challenges pertaining to take BECCS/U from pilots to full-scale projects. Case studies provide deeper insights into the key aspects that come into play for companies that are in the process of setting up value chains for capture, transportation and sequestration or utilization of biogenic CO2.

CO2 from ethanol production

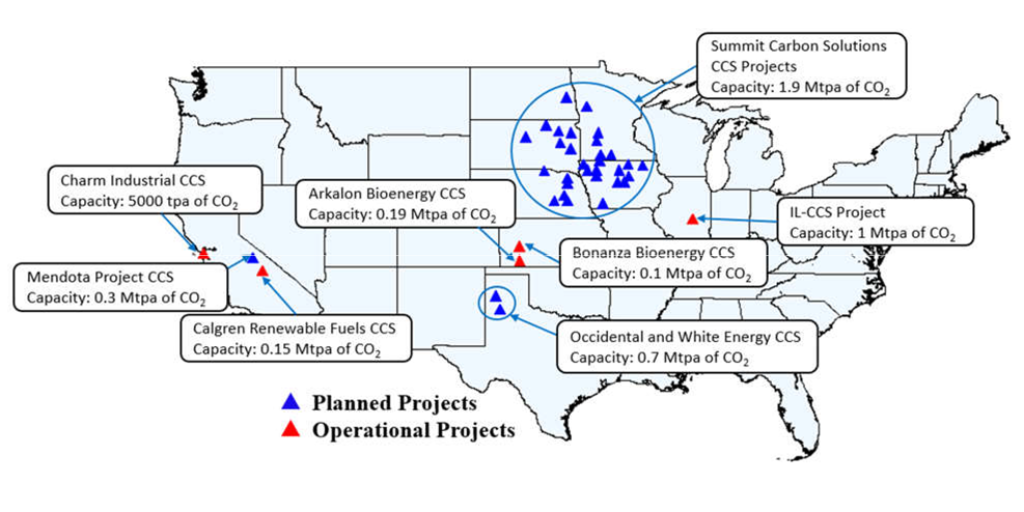

The Archer Daniels Midland Company (ADM), in collaboration with a consortium of academic, industry, and national laboratory partners, have studied the potential for sequestering CO2 generated from an ethanol production plant at multiple sites in the Illinois Basin in the United States. The two projects represented in this case study include the Illinois Basin Decatur Project (IBDP) which represents a large-scale geologic test to inject one million metric tons (mt) of CO2 over a three-year period (1,000 mt/day) and the Illinois Industrial CCS project (IL-ICCS) targeted to demonstrate advanced CCS technologies at industrial scale facilities and inject and store one million mt of CO2 per year (3,000 mt/day). The demonstrations were coupled with development of the Intelligent Monitoring System (IMS) program to develop and validate software tools.

The Illinois Basin region projects have paved the way for deployment of large-scale BECCS facilities in the US. IBDP and IL-CCS projects have demonstrated industrial application of BECCS technology in the Midwest with environmental and economic benefits ranging from lower emissions to lower capital costs compared to other CCS technologies. Onsite CO2 emissions were lower and the process demonstrated GHG reduction efficiency of 94% based on using Midwest electricity grid average. Reduction in the carbon footprint of fuel ethanol was accompanied with lower operational expenses compared to other forms of CO2 capture.

Ethanol biorefineries can be the most promising sector for BECCS deployment as it is the most mature and technology ready bioenergy industry. As of 2022, there are currently 192 operating ethanol biorefineries in the US. According to Renewable Fuels Association, if every ethanol biorefinery in the US deployed CCS technologies with their facility, around 45 million mt of CO2 could be removed from the atmosphere every year. In order to reach the full BECCS potential, it is necessary to deploy BECCS in various energy sectors alongside biofuels including the pulp and paper industry, the cement industry, waste to energy plants and bioelectricity.

Apart from CCS, additional applications can also include development of CO2 based chemicals and products including carbonates, biochar, fertilizers, alcohols, fuels, acids as well as the potential for use in enhanced oil recovery from subsurface rock formations between wells.

Figure: operational and planned BECCS/BECCUS projects in the US