Integration of anaerobic digestion with Power-to-X technologies

This IEA Bioenergy Task 37 report aims to provide an overview of the role that anaerobic digestion can play in Power to X technologies. The objectives are to:

- Outline processes which integrate anaerobic digestion with electrolysis (Chapter 2)

- Detail the design evolution of an experimental laboratory biomethanation process (Chapter 3)

- Examine real world circular economy applications of integration of anaerobic digestion with power to methane systems (Chapter 4)

- Assess future applications integrating anaerobic digestion with Power to X technologies such as production of methanol and ammonia (Chapter 5)

- Discuss optimal routes and applications for Power to X technologies.

Citation: Murphy, J.D., Rusmanis, D., Gray, N., O’Shea, R. (2024) Circular economy approaches to integration of anaerobic digestion with Power to X technologies, Liebetrau, J. (Ed.) IEA Bioenergy Task 37, 2024:1.

Many countries and geopolitical regions have ambitions of achieving net zero carbon by 2050 (US and EU) or 2060 (China). In advance of this, it is expected that a near zero carbon electricity system will be achieved in many jurisdictions around 2035. This will lend itself to electrification and associated decarbonisation of energy as much as is practicable; examples include battery electric vehicles and heat pumps for heating. However, in many countries it is seen that the future resource of renewable electricity (from wind and photovoltaic) will surpass the demand for electricity during substantial periods of time; hydrogen will be produced via water electrolysis to utilise larger resources of electricity or to facilitate electricity produced at times of low electrical demand. This renewable hydrogen will be used to displace existing fossil fuel sourced hydrogen used in industry, but beyond this renewable hydrogen will find new uses in the energy sector. Future markets for renewable hydrogen could include for direct use in transport such as in fuel cell vehicles for long-distance haulage. There may even be a limited market for hydrogen storage as a source of dispatchable electricity in periods where, for example, the wind profile decreases for long periods. The authors believe there will be a future role for renewable power to produce other energy carriers and chemicals. A pathway to convert this hydrogen to a renewable hydrocarbon is to react with biogenic CO2. One of the most prominent sources of high concentration biogenic CO2 may be from biomethane systems.

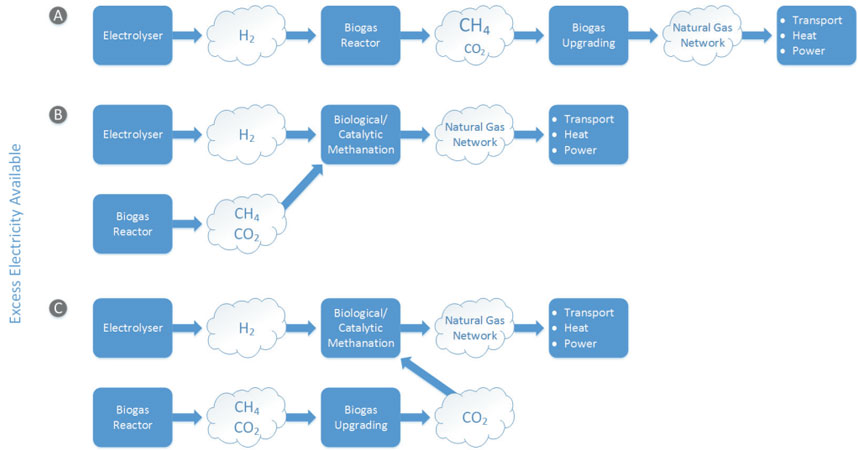

Generically known as ‘Power to X’ technologies, these technologies will produce renewable hydrogen molecules, which can be integrated with anaerobic digestion systems – reacting with biogenic CO2 from the biogas system – for production of additional methane (CH4), and for production of methanol (CH3OH: worldwide production of 110 million tonnes per annum). Power to X also includes for production of ammonia (NH3) which has worldwide production of 160 million tonnes per annum.

One of the primary pathways of Power to X is power to methane (4H2 + CO2 = CH4 + 2H2O) whereby biogenic CO2 is reacted with renewable hydrogen from water electrolysis using renewable electricity. A significant part of this report outlines the logistics of such systems when integrated with biogas facilities, including the narrative of a research laboratory in developing technologies that may be used as a biogas upgrading process. The starting point of the research lab was batch reaction of CO2 and H2 via hydrogenotrophic methanogens; the end point was a successful lab scale demonstration of a three-stage continuous ex-situ biological methanation rig. Several case stories are expanded upon including for demonstration and pre-commercial applications of catalytic and biological processes. An exemplar is detailed where an electrolyser and an ex-situ biomethanation system are situated within a wastewater treatment facility where oxygen generated during electrolysis may be valorised in the aeration basin. This in turn could reduce pumping of air by a factor of 5, and in so doing reducing the carbon footprint of the wastewater treatment facility by 40 %. The hydrogen can be used to upgrade the biogas from sludge digestion to biomethane suitable for compressed natural gas trucks, and the remaining hydrogen may be used to power fuel cells in heavy commercial trucks.

For net zero, decarbonisation must go beyond energy systems and extend to chemical manufacturing. Power to methanol is examined as a substitute for natural gas sourced methanol. Green methanol is seen as one of the important routes to decarbonising shipping. A future constraint will be limited resources of biogenic CO2; fermentation and biomethane industries (with their by-product of concentrated cheap sustainable CO2) can serve as a short-term solution of finite resource. A present source of low carbon methanol is steam reforming of biomethane.

The present day (2023) barriers to green ammonia production are the availability of significant resources of green hydrogen and the requirement for bunkering (and associated ship refuelling) in numerous strategic ports across the planet. Power to ammonia does not require biogenic CO2 and can use the nitrogen that is resplendent in the air in the Haber-Bosch process. Green ammonia will be required to reduce the carbon footprints of fertiliser production and conventional agriculture. The application in shipping may not be straightforward considering the toxicity of ammonia.

Figure: different pathways that can be used to integrate an electrolyser at a biogas facility (from Persson et al., 2014).