Production of chemicals and materials from direct thermochemical liquefaction

The full report is available here

The burgeoning demand for energy and materials, coupled with the imperative to reduce greenhouse gas emissions, has amplified the focus on sustainable bio-resources like biomass. Biomass, being a renewable and fairly abundant resource, holds promise for the production of fuels, chemicals, and materials in a sustainable manner. Two prominent direct thermochemical liquefaction technologies, Pyrolysis and Hydrothermal Liquefaction (HTL), are pivotal in unlocking the potential of biomass. This report – produced by IEA Bioenergy Task 34 – delineates the principles, potential, and challenges inherent to these technologies, along with the outlook for deriving valuable products.

Pyrolysis is the thermal decomposition of a material under inert conditions. Biomass pyrolysis results in the formation of solid, liquid, and gaseous products. When it is desired to maximize the liquid product, fast pyrolysis is applied, applying temperatures of around 500°C and rapid condensation of the vapours. For clean woody biomass up to 70 wt.% of a liquid product can be obtained. About 15 wt.% of the biomass is converted into charcoal and the remaining 15 wt.% to non-condensable gases. Importantly, the minerals present in the biomass are not, or only minimally, transferred into the oil. The ashes (minerals) are readily collected from the process and can be re-used (e.g. fertilizers). Fast pyrolysis of biomass is performed on a commercial scale, the annual production capacity is > 150 kt.

Hydrothermal liquefaction (HTL) is a thermochemical conversion process that converts wet biomass (e.g., algae, sewage sludge, wood, food waste, organic wastes), into a high-energy density liquid ‘biocrude’. An advantage of HTL is its ability to process wet biomass, reducing the extent of dewatering or drying required, which can be energy-intensive and costly. Some challenges associated with the process include the combination of high-temperature and high-pressure required in these processes and fouling of the equipment. Generally, any biomass with high organic matter can be processed in HTL, albeit with varying levels of biocrude quality and/or yield. The main product from HTL, biocrude, is traditionally used to produce liquid transportation fuels. Still, potential applications for materials and chemical applications are being explored.

Main conclusions:

Comparing pyrolysis and HTL, pyrolysis opportunities primarily engage in separation technologies to parse bio-oil into valuable fractions, while HTL opportunities delves into downstream conversion to utilize the carbon content in its aqueous phase. This focus disparity makes it challenging for HTL to borrow from pyrolysis advancements due to differing bio-oil chemistries. However, pyrolysis could potentially benefit from HTL’s aqueous phase solutions, as the challenges with aqueous fractions are likely parallel in both processes.

Numerous opportunities exist for creating materials and chemicals from biomass pyrolysis, particularly fast pyrolysis. Fast pyrolysis can yield substantial liquid products, also known as bio-oil, composed of various complex components. While fast pyrolysis bio-oil has established uses as an energy carrier, exploiting its complex chemical structure could unlock more applications. Different conversion processes could transform bio-oil into a range of valuable chemicals.

Fractionation methods are discussed for obtaining functional fractions from bio-oil, which can serve as precursors for green chemicals and materials. Many of these opportunities have been realized at a TRL of 6-8. Despite the promising outlook, challenges like scalability, bio-oil complexity, and product consistency need to be addressed to fully realize this sustainable and circular bio-economy pathway.

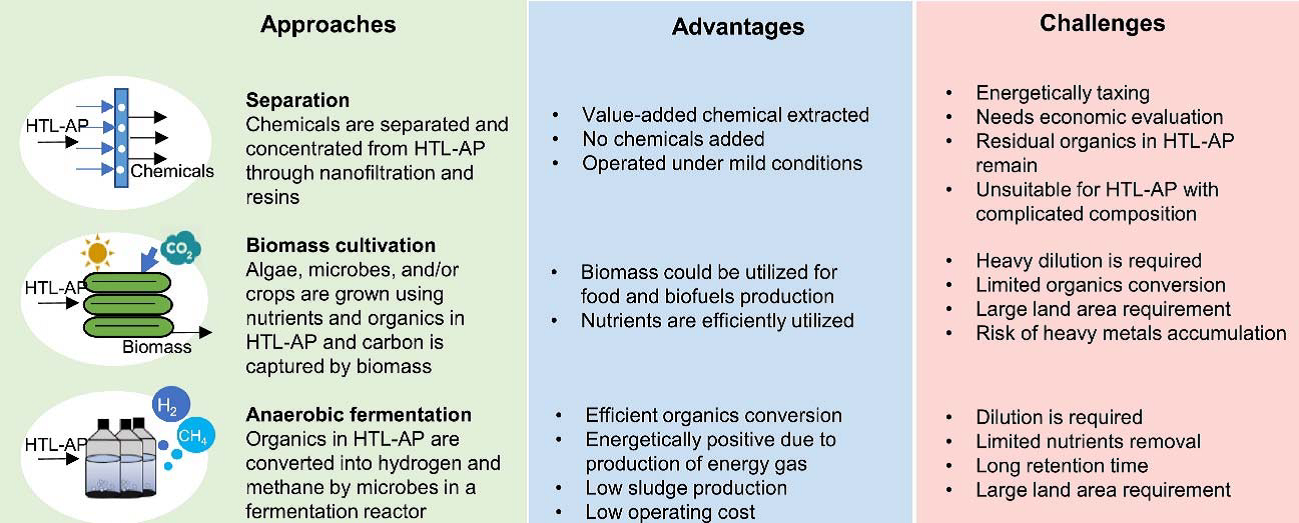

Purification of chemicals and materials from hydrothermal liquefaction (HTL) is also an area of much interest. While there are opportunities for producing materials and chemical from HTL biocrude, the area of most research for producing chemicals from HTL lies in valorisation of the carbon and nutrient content in the aqueous phase. The biocrude component, although laden with useful compounds, requires sophisticated methods for efficient separation and refinement due to its high boiling point and the wide range of polar and oxygenated compounds. The HTL aqueous phase, on the other hand, is a rich mixture of organic and inorganic compounds, providing prospects for carbon and nutrient recovery. However, its complexity, dilute nature, and the presence of low-value components constitute significant hurdles for straightforward extraction, valorization, and economic viability. Advancements in thermochemical conversion processes such as catalytic hydrothermal gasification (CHG), biomass cultivation techniques, anaerobic fermentation, bioelectrochemical systems, hydrothermal gasification, and HTL recycling might offer solutions to these issues. Nonetheless, these options are currently at a low TRL and the quest to unlock the full potential of these resources necessitates more efficient, cost-effective processes.

Figure: Comparison of the state of technology of different HTL aqueous phase valorization approaches. Source: Watson et al (2020), Progress in Energy and Combustion Science.