Technical Guidelines for the Design of Low Emission Wood Stoves

Wood stoves are popular as a primary or complimentary heat source. However, unwanted by-products are formed and emitted during combustion of wood logs. These emissions continue to be a concern for the environment and for public health. Correct operation and proper design of wood stoves are key to minimize harmful emissions, and both are equally important. This report summarizes the experience from several recent research and development projects for low-emission wood stoves. The guidelines in this report focus on technological measures, e.g., stove design, flue gas cleaning and automatic control systems.

Full report available here

Design of Low Emission Wood Stoves – Technical Guidelines

Emissions considered in the report are particulate matter (PM), carbon monoxide (CO), organic gaseous carbon (OGC) and nitrogen oxides (NOx). Reducing these emissions from wood stoves requires to optimize the entire system (stove, chimney, and additional equipment) and ensuring that the oven is operated with proper draft and the correct fuel. Downstream equipment, such as particle filters and flue gas fans will influence draft in the stove, while (automatic) control systems can adjust air flow to the different phases in the combustion process.

The guidelines cover both primary and secondary measures. Primary measures aim at controlling combustion so that unwanted reaction products are either prevented or burned out. Secondary measures include the removal of emissions downstream of the combustion chamber (e.g., at the chimney). The recommendation is always to ensure proper installation and operation of the wood stove and to optimize the stove as much as possible with primary measures before applying secondary measures. Secondary technologies are thus meant to reduce the remaining levels of pollutants.

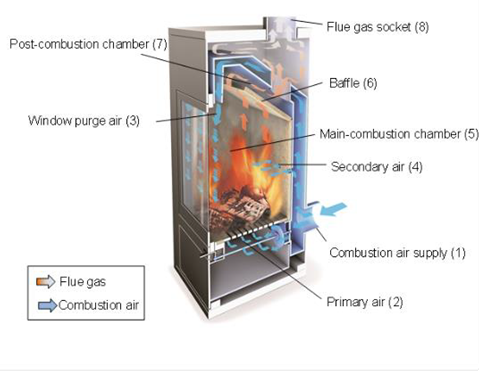

Primary measures reviewed in the report are: construction of the combustion chamber (geometry, insulation, windows), air staging, and draft control. Geometry and insulation of the combustion chamber influence the temperature distribution in the oven. Air staging and draft control the local availability of oxygen. Sufficient oxygen and high temperatures are equally important in achieving a complete burnout (reducing CO and OGC), while excessive oxygen and temperature promote formation of NOx and soot-precursors.

Once formed and beyond the reach of primary measures, unburned materials can be catalytically oxidized downstream of the combustion chamber, while particles can be removed with the help of electrostatic filters in the chimney. There are currently no secondary measures against NOx, as wood stove NOx-emissions are well within legal requirements using primary measures (especially air staging) alone.

As wood stoves are operated in batch-firing mode, there is no single optimal operating point. With sensors, actuators, and electronic control systems becoming cheaper and more reliable, automatic control systems are expected to play an increasing role in wood stoves. The main parameters to control are the amount and distribution of combustion air.

The development of new, modern, and low emissions wood stoves is not only driven by legislation, but also by the request of the end-consumer and funding schemes and market labels such as the Nordic Swan Ecolabel, the French Flamme Verte and the German Blauer Engel. With regards to new legislation, US has in 2020 established new legislation and testing methods and Europe will have a common legislation via Ecodesign from 2022. Real life testing is being introduced with the German Blauer Engel method and will increase the need of focus on the development of improved and robust combustion control within the wood stove.

The technical guidelines in this report should be regarded as an overview or a reference work, not as an in-depth review of available technologies or stove designs.

The main conclusions of the report were also presented at an IEA Bioenergy webinar. The presentation is available here: https://www.ieabioenergy.com/wp-content/uploads/2021/05/Warming-Jespersen-Technical-guidelines-for-design-of-low-emission-stoves-Workshop-2021.pdf

Figure: Wood stove layout and focus points for optimization