New Publication – Emerging Gasification Technologies for Waste & Biomass

Gasification is a flexible thermal conversion process with wide-ranging applications in sectors such as heat and power generation, transport fuel and chemicals production. This report, developed by IEA Bioenergy Task 33, provides a closer examination of a number of emerging gasification technologies, i.e. technologies that are novel or have different characteristics than state-of-the-art gasification technologies.

Full report available here: Emerging Gasification Technologies_final

There are many things that are in favour of gasification as a technology; the combination of fuel flexibility and product flexibility, high conversion of the fuel, technologies suitable for a variety of scales, etc. are technical aspects that means that gasification has fewer feedstock and technical limitations than other advanced biofuel technologies.

So far the commercial use of gasification has been mostly limited to CHP and district heating and a handful of co-firing applications. Until recently, the development of advanced processes and broader application of biomass gasification for synthesis gas has been impeded by competition from low-cost fossil fuels combined with policy uncertainty as well as insufficient incentives from policy interventions. However, the field of biomass and waste gasification is experiencing a structural transformation. Research and policy interest in efficient resource utilization continues to grow with biogenic carbon becoming a more valuable commodity. Against this backdrop, opportunities open for new gasification technologies that can upgrade low-value biomass and waste streams to higher value-added products.

The scope of the report is focused on emerging gasification technologies, technologies that are novel or have different characteristics than the state-of-the-art technologies. 10 examples of emerging technologies that indicate the diversity of technical solutions breaking into the waste and biomass gasification market are chosen for closer examination. The objective of this report is twofold:

- To provide a methodological framework for the assessment of emerging gasification technologies;

- To technically describe, characterize and examine a selection of emerging technologies in the area of biomass and waste gasification using the developed framework.

The approach is centered on the assignation of discrete technology readiness level (TRL) scores to the essential process sub-steps common to all gasification technologies, namely, feedstock handling, gasification reactor with heat supply, product gas separation and cleaning, and integrated operation. Information is collected from various publicly available sources and used as far as possible to identify process configuration and compile process profiles based on a standard template.

The following technologies were assessed:

| Gasification Technology | Developer | Integrated System TRL

(1-9) |

Background |

| Two-stage gasification with integrated catalytic hot gas cleaning | Renergi Pty Ltd. (Australia) | 6-7 | Developed to convert various biomass streams (e.g., forestry wastes and agricultural wastes) to heat and power in CHP applications |

| Microwave-assisted ‘Imbert-type’ gasification | Endeavour Energia S. r. l. (Italy) | 5-6 | Can be used to upgrade waste and biomass feeds, such as rice and wheat husks, woody biomass, sludge from anaerobic digestion and litter from animal farms to electricity, heat, and biochar. |

| Heliostorm Ionic gasification | Cogent Energy Systems (USA) | 5-6 | Ultra-high temperature ionic gasification technology designed for small-scale waste to energy applications |

| MIGH Moving injection fixed bed | Wildfire Energy (Australia) | 3-4 | Based on a batch process where a sealed bed of unprocessed biomass and waste feedstock is upgraded to syngas by a stream of oxidant moving through the bed |

| Entrained-flow cyclone gasification | MEVA Energy AB (Sweden) | 7-8 | Small-scale biofuel cogeneration system built around an entrained-flow cyclone gasifier designed to process crushed pellets and sawdust. |

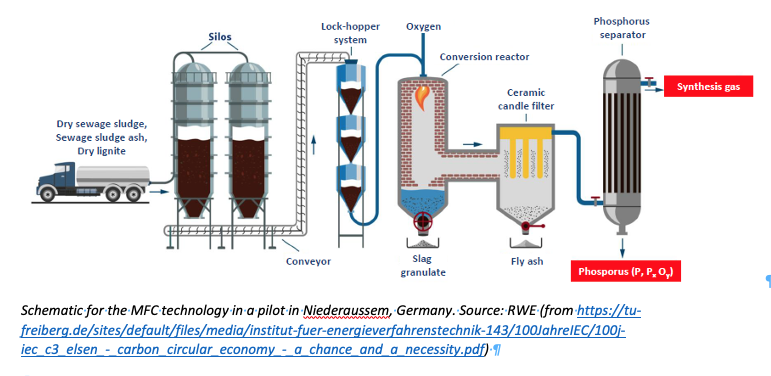

| Multifuel Conversion (MFC) technology | RWE Power AG (Germany) | 2 | High temperature entrained-flow gasification, optimized to achieve reduction of phosphates to gaseous phosphorous compounds. Focus on recovery of carbon and phosphorous from sewage sludge and other phosphorous-rich feedstocks |

| Plasma (tar) gasification & Plasma Refining System | Plasco Conversion Technologies (Canada) | 5-6 | Three-step process configuration in which municipal solid waste is subjected to moving-bed pyrolysis; the resulting solid fraction is oxidized for heat recovery, while the volatiles are exposed to plasma plumes for cracking resident tars. |

| RadGas Fluidized-bed gasification | Advanced Biofuel Solutions Ltd. (UK) | 3-4 | Two-stage approach combining an oxy-steam fluidized bed gasifier with a catalytic chamber (plasma converter unit) to convert RDF into SNG. |

| Inclined rotary gasification | SUNY Cobleskill/Caribou Biofuels (USA) | 5-6 | Portable small-scale gasification in which untreated (wet) waste streams, such as municipal solid waste, forestry residue and non-hazardous site wastes can be upgraded to electricity, biofuels and char in an inclined rotary gasifier coupled to a gas cleaning unit |

| Hydrothermal Gasification | TreaTech SARL (Switzerland) | 2 | Hydrothermal gasification (supercritical) to be used to upgrade liquid wastes, such as sewage sludge, to clean water, biogas and mineral salts (allowing effective recovery of phosphates). |

In this work, the sample consisted of only 10, and also very diverse technologies. The limited number of technologies addressing the same feedstock and application prevents drawing any conclusions on the status of different types of gasification systems and application.

However, it can be noted that two systems at least addressed sludges with the ambition to recover nutrients. Sludge gasification, although also being developed in the past to some limited extent, has typically not been in the focus of gasification developers as the feed is – by gasification standards – very high in both moisture and ash, thereby limiting the efficiency and gas heating value. But nutrient recovery can be a new demand on sludge systems that may work in the favour of gasification.